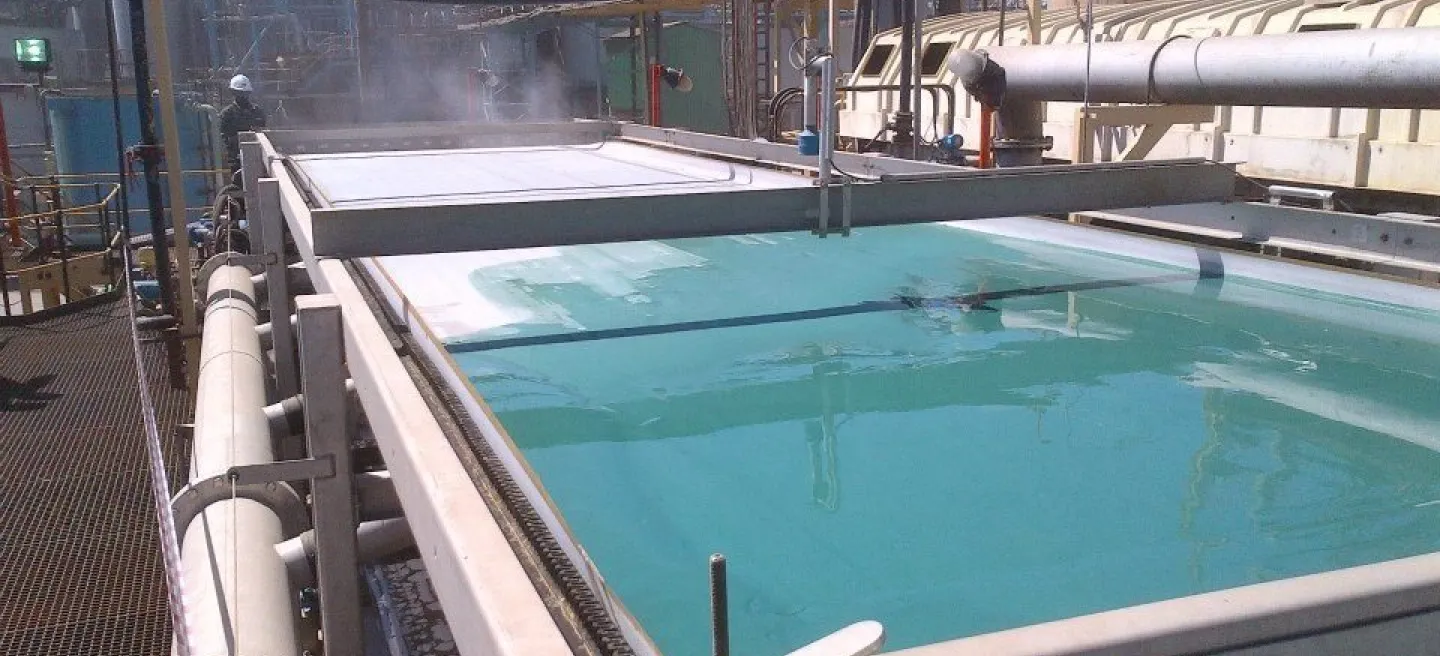

Hasler Group manufactures an innovative range of continuous vacuum filtration equipment. Regardless of sludge characteristics and flowrate, with high level of certainty, Ū-Tec will be able to select an efficient and reliable industrial solution for vacuum liquid-solid separation. Hydrometallurgy, phosphoric acid production, and FGD are areas where Hasler vacuum filters have a long and successful track record.

Feedback from operation in demanding conditions has accumulated in know-how which allows Hasler vacuum filters to achieve:

- high washing efficiency,

- maximum recovery of 99,9%

- high reliability (availability up to 98%)

- ease of maintenance

Hasler vacuum filters allow you to:

- MAXIMISE DRYING of the cake to eliminate the need for ovens

- OPTIMIZE the recovery of the liquid

- OBTAIN MAXIMUM CONCENTRATION of the filtrate. Ex: 28% for phosphoric acid

- REMOVE an element from the cake, e.g. salts / chlorides

- IMPROVE ENERGY EFFICIENCY: consume less water and electricity

- FILTER on time and on budget

- ENSURE THE SAFETY of operators and installations. e.g. CE-standard protective grids

- REDUCE OPERATING COSTS and the risk of shutdowns

- DEVELOP NEW filtering PRACTICES for new products

Wide range of materials is available to withstand abrasion and corrosion (stainless steel 316, 904L, duplex, super duplex steel, FRP, HDPE and other non-metallic materials).

In order to achieve the best process results, process and mechanical audits are available as a service. Dewatering and filtration efficiency can be tested in a lab or on site. Testing allows to develop optimal filter and washing system (co-current or counter-current) configuration and issue a process guaranty.

Typical applications for our horizontal vacuum belt filters:

- lithium battery black mass filtration

- wet process phosphoric acid filtration

- fertilizers

- gold and silver refining, cyanide recovery

- acid leaching of copper, nickel, zinc, cobalt

- spodumene dewatering

- lithium brine

- rare earth elements

- gypsum dewatering

- tailings dewatering

- fly ash

- alumina

Ū-Tec is the official Hasler vacuum filtration equipment agent in the Baltic, Nordic countries and Central Asia.

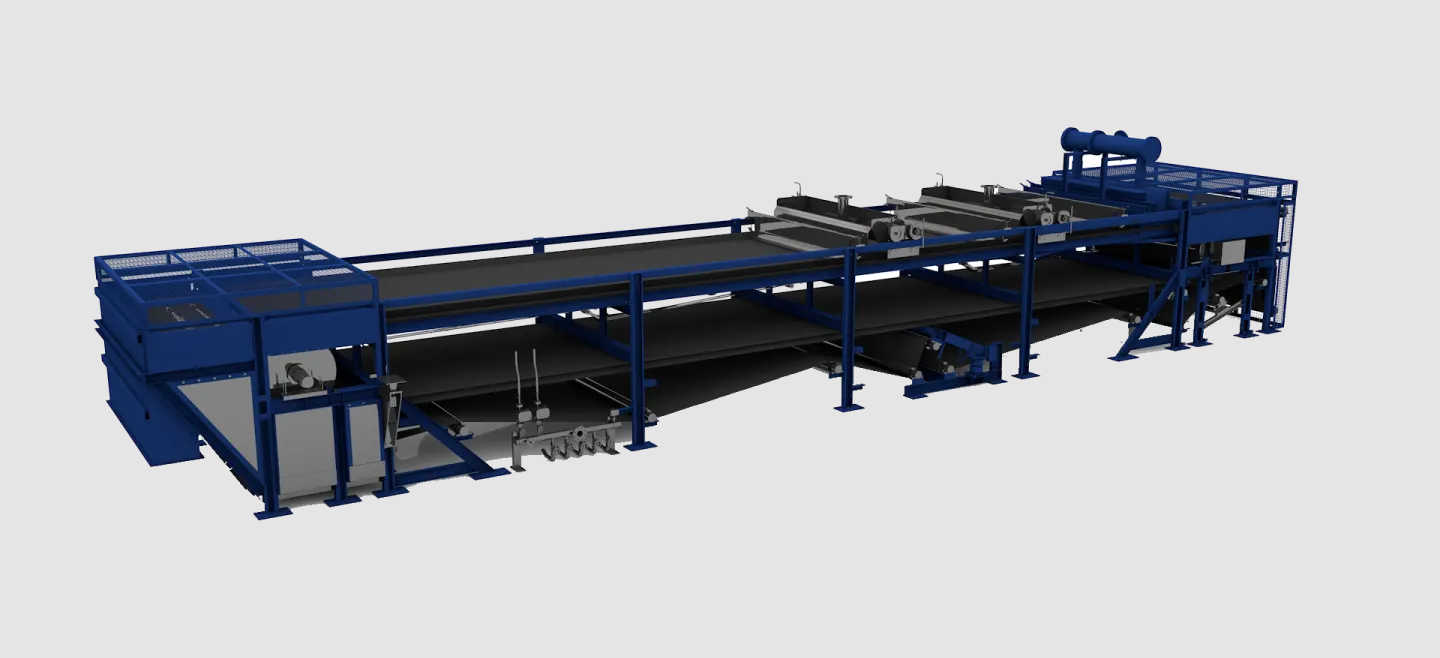

PHILIPPE horizontal vacuum belt filters

Filtres Philippe® horizontal belt filters provide an ideal solution for your mineral or bulk chemical processing applications. New technologies and years of expertise guarantee 98% uptime to ensure you meet your processing goals.

In a filter cloth and rubber belt system, the belt is not only a key operating component, but is also a significant portion of the cost of the system. With this in mind, HASLER Group manufactures and tests the belts in dedicated facilities. Each belt is run on a proprietary robotic machine to remove residual stresses, true edges, cut grooves and bore drain holes. Our belts feature patented chemically bonded belt curbs, and are factory spliced and hot vulcanized to ensure a long operating life.